|

Today many fertiliser formulations exist to cater for every aspect of plant nutrition. These include

fertilisers for field crops, gardens and nurseries. There are slow release, liquid foliar feed, and hydroponic feed formulations.

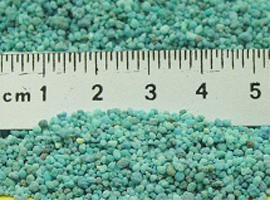

Osmocote (left), a slow release fertiliser, and urea

formaldehyde (right), a

fertiliser that is applied dissolved in water.

The following are points to consider when selecting fertilizers:

| A complement of all essential elements must be supplied to plants either as a single formulation or as a combination of a few formulations.

|

| Manufacturer's recommended application rates should be followed; use of higher rates may cause severe damage or death due to salt burns.

|

| The same mix and fertiliser rates should not be used for both seedlings and larger plants because they do not have the same nutritional needs.

|

| The performance of any fertiliser (release mode and rates at varying temperature and moisture levels), durability (i.e. whether it will be leached away with the first irrigation or rain), and pH, should be observed, and actions implemented to counter any long term detrimental effects. Alternatively, a more appropriate formulation should be selected.

|

| There is a reduced fertiliser need when plant growth is low during dry seasons and winter.

|

| Requirements vary between species. For example, annual cereals have very different nutritional requirements than perennial trees.

|

| Fertiliser(s) should provide a relatively constant nutrient supply rather than fluctuating high and low levels. Combinations of slow-release granular formulations and immediately available liquid fertilizers may provide the constant nutrient

supply required.

|

| Liquid fertiliser can produce a rapid growth response in plants with reduced

vigour, or rapidly correct a nutrient deficiency. However, liquid

fertilisers are readily leached from the medium.

|

| The formulation should be easy to apply.

|

| Cost per unit should be considered in terms of longevity, application rates, time and labour cost for application. A cheap

fertiliser, which may need to be applied in large amounts and frequently, may cost more than an expensive formulation requiring only a single, small or

annual application.

|

| Prepared potting mix containing slow-release fertiliser should not be steam sterilised at 100°C as such treatment can destroy some or all of the slow-release properties of the

fertilisers and may lead to rapid release of nutrient salts that may injure or kill plants. Pasteurising mixes at

60-65°C for 30 minutes does not release toxic levels of nutrient salts.

|

| Soluble nutrients are continuously released from coated fertilisers during storage of moist mixes, causing the salinity of the mix to increase to damaging levels. Mixes containing coated

fertilisers should be used within a couple of days of preparation, otherwise leaching (over watering) to remove the salts, and nutrients, should be carried out immediately after potting

(Handreck and Black

1984).

|

| Fertiliser should be well mixed into the potting mix whenever possible, rather than applied to the surface. Release rates are more consistent in the mix because temperature and moisture fluctuate less than on the surface.

Fertiliser applied to the surface may be lost by splashing water, wind toppling plants, pots being weeded, or accidentally bumping or dropping the pot. Nutrients applied to the surface are dependent on water permeating from the surface to wash them into the root-zone, whereas those mixed into the potting mix are released where they are absorbed.

|

| Fertiliser residues, particularly from slow-release formulations, are likely to be present in varying concentrations in any recycled potting mix. To avoid injury from the accumulated salts, their concentration should be measured as the total soluble salts or total dissolved salts extracted in solution from a known volume of media. Alternatively, the electrical conductivity of the solution should be measured. Handreck and Black

(1984) state that approximate maximum allowable electrical conductivity for saturation extract of growing media is 1.4 deciSiemens per metre

(dS/m) for sensitive plants and 2.5 dS/m for moderately tolerant plants. Above these levels deleterious effects on plant growth may occur. Alternatively, before the recycled mix is used, a plant known to be sensitive to salt levels should be planted in the recycled mix and observed for symptoms of high salt levels. Excess salts can be leached from the mix by thoroughly flushing with water, or by combining the recycled mix with new mix to which no

fertiliser has been added. |

[ Back ] [ Next ]

Gio. W. Fichera

|

|